Edge-cut is a common type of damage for rubber tracks used on construction sites. When a machine drives against a curb, stump or sharp/solid object, the edge of the track can bend over, shearing the rubber between the edge of the track and the top of the embedded core metal.

Common cause of edge-cut

After 1000 hours

After 1900 hours

Bridgestone developed innovative Pro-Edge technology to minimize edge-cut damage. Pro-Edge technology is based on the combination of a rounded shape core metal edge design to avoid the build-up of stress concentrations, and additional rubber volume on both the inner and tread sides to make the track edge more durable.

Bridgestone developed innovative Pro-Edge technology to minimize edge-cut damage. Pro-Edge technology is based on the combination of a rounded shape core metal edge design to avoid the build-up of stress concentrations, and additional rubber volume on both the inner and tread sides to make the track edge more durable.

Bridgestone's Pro-Edge technology is now well accepted by many customers and proved in the market. The benefits of Pro-Edge are also proved by Bridgestone's internal testing and by FEM analysis.

Standard core metal

Pro-Edge core metal

47% less stress on the core metal edge compared to a standard core metal.

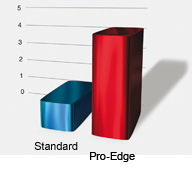

Pro-Edge 4-fold improvement

300mm width track testing data on 3.5ton machine. Graph shows the number of trials made before edge-cut occurs.